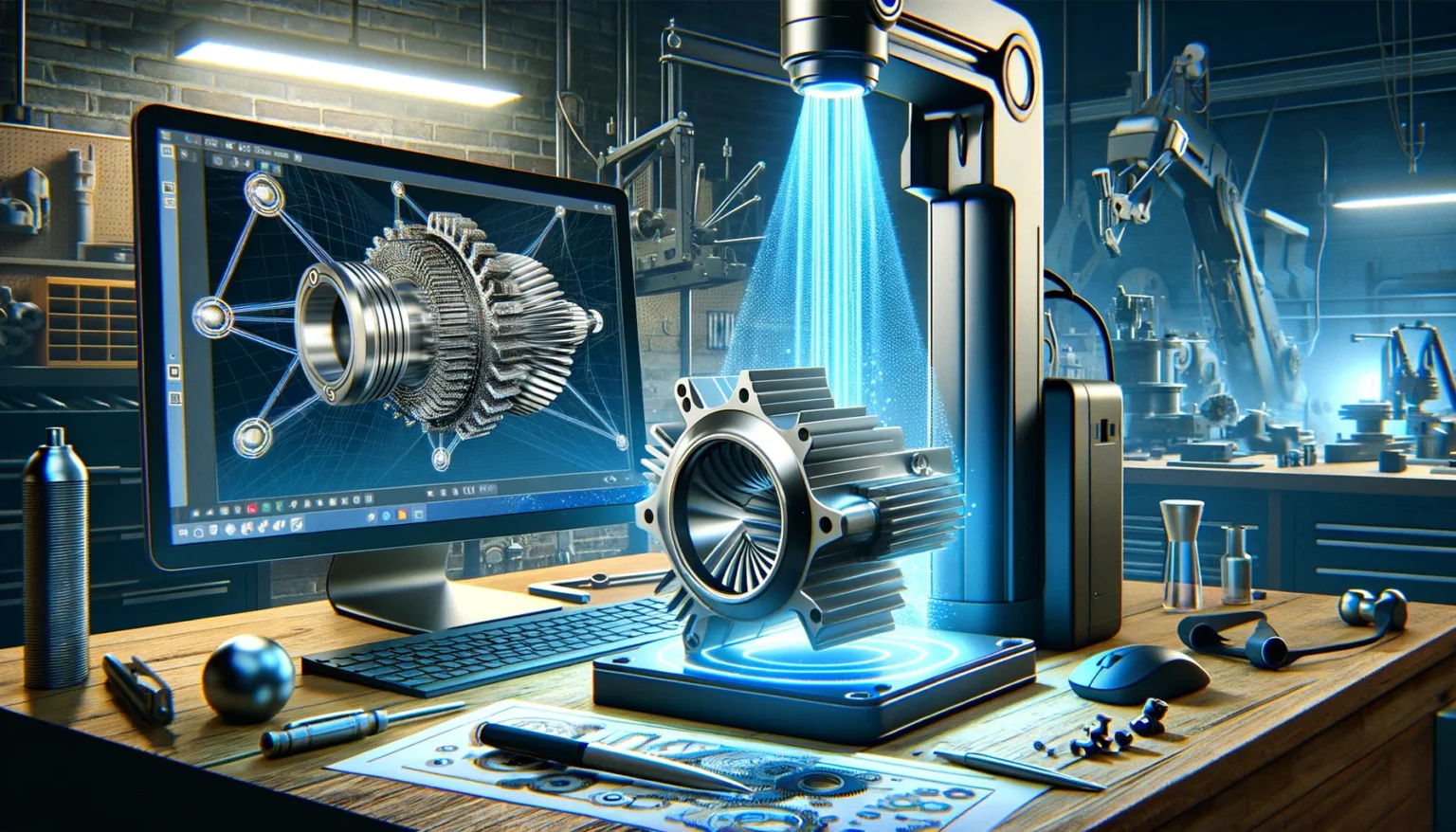

Introduction to Industrial 3D Scanners

Industrial 3D scanners have revolutionized the way measurements and inspections are conducted in various industries. By using advanced technology, these scanners capture precise, detailed 3D models of physical objects, enabling engineers to analyze and improve their designs. With applications in automotive, aerospace, manufacturing, and more Industrial 3D scanner are essential tools for improving quality control, reducing errors, and enhancing productivity.

The Technology Behind Industrial 3D Scanners

At the core of industrial 3D scanning is a combination of laser and optical technologies that enable high-precision scanning of physical objects. These scanners work by emitting laser beams or light patterns onto the surface of an object, and then capturing the reflected signals to create a digital 3D model. The technology is incredibly accurate, capable of measuring dimensions down to microns, making it ideal for high-stakes industries where precision is critical.

Applications of Industrial 3D Scanners

Industrial 3D scanners are used across a wide range of industries, from automotive manufacturing to civil engineering. In automotive design, 3D scanning is used to create detailed models of components for prototyping and testing. Aerospace engineers use these scanners to inspect parts with complex geometries, ensuring they meet rigorous safety standards. Industrial 3D scanners also play a crucial role in reverse engineering, quality control, and maintenance, helping businesses maintain high-quality standards across the production process.

The Advantages of Using Industrial 3D Scanners

The use of industrial 3D scanners offers several advantages for engineering firms. These include improved accuracy, faster data collection, and the ability to inspect complex parts that may be difficult or impossible to measure using traditional methods. The technology enables engineers to identify potential design flaws before production begins, reducing the risk of errors and ensuring that final products meet specifications. Furthermore, industrial 3D scanning is highly efficient, reducing the time and labor involved in inspection and testing.

How Industrial 3D Scanners Enhance Product Development

One of the key benefits of industrial 3D scanners is their ability to enhance the product development process. By creating detailed digital models of physical objects, engineers can test and refine their designs in virtual environments, minimizing the need for costly physical prototypes. This not only accelerates the design process but also leads to better, more optimized products. Additionally, industrial 3D scanning can be used to integrate new designs into existing systems, making it a valuable tool for upgrading or replacing components in complex machinery.

High-End Industrial 3D Scanners for Precision Measurement

For high-budget engineering firms that demand the utmost precision, investing in high-end industrial 3D scanners is crucial. Measurement Solutions, the official distributor of Creaform 3D Scanning products in the UK, offers advanced 3D scanners that cater to the needs of these businesses. With products like digital laser scanners costing upwards of £50K, these tools provide unparalleled accuracy and are built to handle even the most complex measurement tasks. These high-end scanners are ideal for industries where quality, precision, and performance are non-negotiable.

The Role of Software in 3D Scanning

While the hardware of industrial 3D scanners is impressive, the accompanying software is equally important. The software enables the scanned data to be processed, analyzed, and turned into actionable insights. With advanced algorithms, 3D scanning software can automatically detect deviations from the intended design, analyze geometric features, and provide detailed reports. Additionally, these software packages often include integration capabilities, allowing businesses to seamlessly incorporate scanned data into their existing CAD or metrology systems.

Choosing the Right Industrial 3D Scanner

When selecting an industrial 3D scanner, it is important to consider factors such as the complexity of the objects being scanned, the level of precision required, and the budget available. High-budget engineering firms looking for precision and reliability may want to invest in digital laser scanners that offer accuracy down to the micron level. Measurement Solutions provides a range of Creaform 3D scanning products that offer these capabilities, allowing businesses to select the right tools for their specific needs. By investing in quality industrial 3D scanners, firms can optimize their production processes and achieve superior results.

Conclusion

Industrial 3D scanners are essential tools for modern engineering, providing unprecedented levels of accuracy and efficiency in measurement and inspection. As technology continues to evolve, the capabilities of these scanners will only improve, enabling businesses to create even more precise models and streamline their workflows. For high-budget engineering firms, investing in top-tier 3D scanning solutions like those offered by Measurement Solutions can provide a significant competitive edge. As industries continue to demand higher levels of precision, industrial 3D scanning will remain at the forefront of innovation, shaping the future of product development, manufacturing, and quality control.