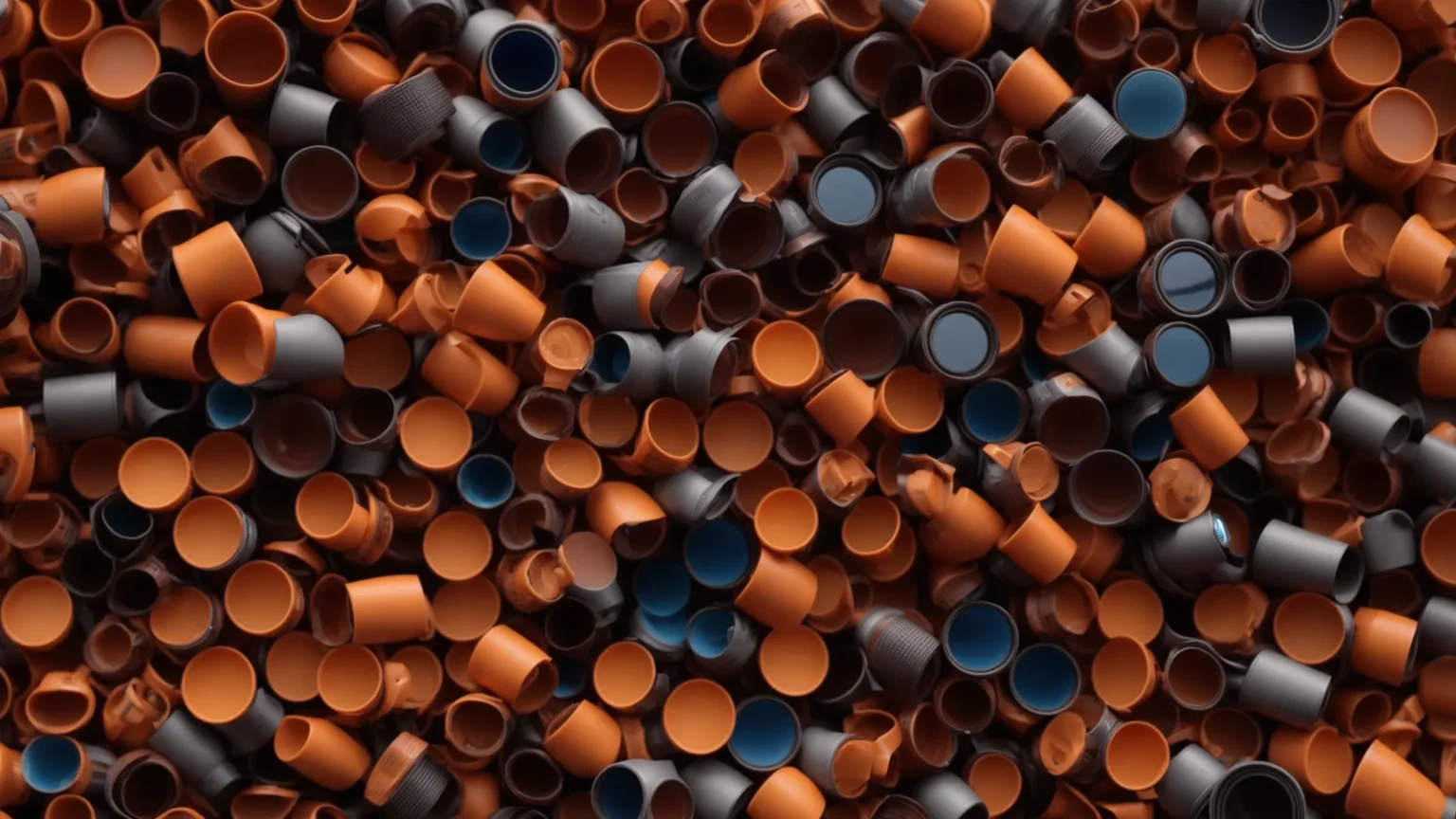

Within the realm of construction, ensuring that materials and components are adequately protected is paramount. This level of consideration extends to seemingly minor, yet essential, items such as plastic pipe plugs and caps. These items play a critical role in maintaining the integrity of piping systems throughout construction phases. They protect against contaminants, damage, and maintain necessary pressure levels. In this article, we’ll explore the numerous benefits these components offer to construction projects.

Protective Measures: Advantages of Plastic Pipe Plugs and Caps

Plastic pipe plugs and caps are essential for protecting piping systems on construction sites. They shield open-ended pipes from dust, debris, and moisture, preventing internal build-up that could impair functionality. They help guard against damage during transportation, reducing the risk of leaks and costly repairs by keeping pipes intact throughout the project.

These flexible plastic components adapt to slight size variations, enhancing their sealing capabilities and chemical resistance. Fitting and removing them is straightforward, allowing contractors to quickly secure pipes during construction and easily access them when needed. This efficiency not only saves time but also reduces labor costs compared to more complex protective solutions.

Cost-Effective Solutions for Construction Projects

Plastic pipe plugs and caps are a cost-effective solution for construction projects due to their affordability compared to metal alternatives. These protective devices reduce project delays caused by compromised piping systems, allowing project budgets to be allocated more effectively. Advanced planning with these tools ensures projects stay on schedule, resulting in financial savings.

Beyond their low initial purchase price, plastic pipe plugs and caps also reduce long-term costs by protecting pipes against environmental factors and damage, minimizing the need for expensive maintenance or replacement. The longevity of plastic construction materials adds to their cost-effectiveness, as they can withstand various conditions without significant wear and tear, making them a sustainable choice for future projects.

Enhancing Durability with Plastic Protection in Construction

Construction project durability is influenced by the quality of components and protective measures taken during assembly. Plastic pipe plugs and caps ensure airtight systems, preventing premature deterioration due to corroding elements. Their inherent strength provides sturdy coverage during construction activities, ensuring pipes arrive on-site and are installed without compromise.

Many plastic pipe plugs and caps contain UV stabilizers, allowing them to withstand prolonged sunlight exposure without losing their protective qualities. When used as part of a comprehensive protection strategy, plastic covers can significantly extend the operational lifespan of piping systems, enhancing the resilience and safety of the final construction project.

Improving Safety on Construction Sites with Pipe Plugs and Caps

Plastic pipe plugs and caps are crucial in construction protocols, as they enhance safety measures by sealing exposed pipe ends, reducing the risk of injury from sharp edges or pressurized substances. These protective elements also contain potentially hazardous materials, safeguarding not only the workforce but also the surrounding environment during project development.

They also prevent accidental spills and leaks, reducing the risk of onsite accidents and associated liabilities. The use of plastic protection aligns with regulatory standards set by oversight bodies, demonstrating a commitment to strict safety protocols and fostering a culture of mindfulness and caution in the construction industry. Thus, the integration of plastic protection in construction protocols is essential for project success.

Streamlining Construction Processes Through Innovative Use of Plastic Covers

Plastic materials have revolutionized industrial processes, including construction. The design and use of plastic pipe plugs and caps enable quick installation and removal, facilitating smoother transitions between phases. These solutions reduce the likelihood of damages and obstruction within piping systems, allowing construction teams to proceed without interruptions for repairs or maintenance. This leads to enhanced productivity and a focus on project planning.

Plastic technology innovations have evolved these tools to offer specialized functionalities, such as temperature-resistant caps and adjustable-diameter plugs. These products integrate seamlessly with unique construction requirements, demonstrating the importance of precision and reliability in construction efficiency.

Altogether, plastic pipe plugs and caps represent a construction necessity that is as prudent financially as it is operationally. They ensure that the systems which are vital to a project’s success are shielded against numerous potential adversities. The adoption of these cost-friendly, durable, and safety-enhancing tools demonstrates a thorough understanding of the intricacies of sound construction practices.